Seratec in a few dates

1970 BIRTH

Creation of Seratec (SERum TEChnologies) by Pierre Réveilleau in Epinay-sur-Seine.

Family LLC specialized in medical biology and biotechnology, Seratec operates the research laboratory and manufacturing workshop of the Eurobio Laboratories.

Seratec practices its expertise in fine organic chemistry in the fields of medical diagnostics and biochemistry, manufacturer of reagents for research and synthesizing products for the dosage of compounds of biological interest.

1984 EXPANSION

In order to expand its catalog, the Seratec team pursued the development of new chemical entities for therapeutic purposes on behalf of public and private laboratories.

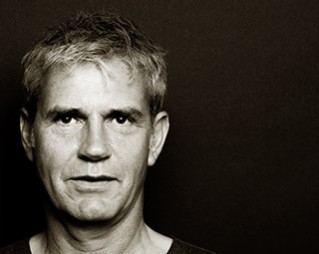

1992 ARRIVAL OF ANTOINE RÉVEILLEAU

The split with Eurobio occurred in 1992, with the arrival at Seratec of a Pharmacist, Antoine Réveilleau, son of the founder, as Scientific Director, and in 1994, a PhD in chemistry, Jacek Ropenga as director of the Organic Synthesis Laboratory.

2000 CONQUEST

To meet the demand of international pharmaceutical customers, this team decided to invest nearly four million Euros in a production unit that complied with American quality standards, considered the most stringent cGMP. After two years of design with an engineering company, work began on the future site of Courville-sur-Eure.

2003 FDA ACCEPTABILITY OF COURVILLE PLANT

The inauguration took place in 2003, immediately followed by an inspection by the Food & Drug Administration (PAI) leading to the acceptability of the site for the cGMP standard, essential for selling active ingredients in North America.

2006 THE NEW BEGINNING

Victim of its success, responsible for organizational problems in the difficult transition from an artisanal structure to an industrial entity, Seratec was summoned before the commercial court for a labor dispute and saw its commercial management suspended. At the same time, in the US Seratec was negotiating its model of excellence in the manufacturing of active ingredients at listed multinational companies. Its innovative company model combining its chemicals business with registration (CMC) of rare or orphan active ingredients with the health authorities then found its success by concluding contracts that gave it a fresh start.

2007 THE cGMP COMPLIANCE CERTIFICATES

Seratec undertook its restructuring by reorganizing its teams and assigning their activities under the direction of experienced managers who joined the leading duo.

At the same time, Seratec continued its repositioning strategy by multiplying the registrations of active ingredient files from its catalog. Seratec established its innovative company ambitions by implementing collaborative electronic project management tools (intranet) and a document management tool with its customers (extranet).

It is also in 2007 that the French drug agency conducted the first European inspection of Seratec, leading the company to obtain its first three certificates of compliance with good practices (GMP). Two years later another inspection by the US FDA led to the approval of 2 new active ingredients on the US market.

2010 SUCCESS STORY

Since then Seratec holds more than 12 active ingredients files submitted and accepted by Western health authorities, including a centralized procedure and a sNDA, as well as 17 GMP certificates for its APIs.

With its strong team, the pharmaceutical quality system at Seratec has been reinforced and expanded by its employees’ experience and many audits by its customers. Moreover, in its new digital policy, Seratec takes the compliance of electronic systems with GMP very seriously, such as the electronic document management and electronic quality management of our processes. The systematic analysis of quality risk and a proactive approach to all company processes are also implemented.

2018 WE’RE HERE !

After many years of formation, Seratec aims to implement 21st century GMP tools in which the keystone is combining an understanding of the product and the procedure, and their variability, in a new pharmaceutical paradigm. We aim to implement total quality tools in an improved approach. These ambitions are reflected in our approach to excellence in business, in which new concepts of development and manufacturing of active pharmaceutical ingredients, process validation, statistical control of processes, and the integration of the pharmaceutical quality system are organized… just to name a few.